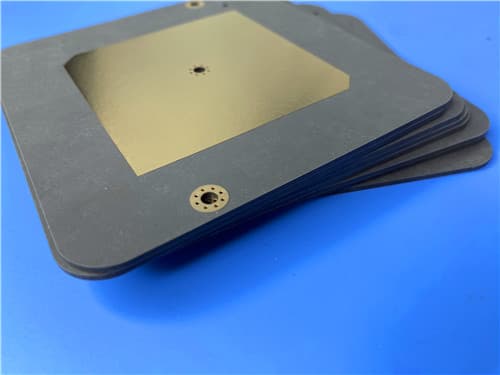

RT/duroid 5880 2-Layer 62mil ENIG PCB for Millimeter Wave Applications

1.Introduction of RT/duroid 5880

Rogers RT/duroid 5880 high frequency laminates are PTFE composites reinforced with glass microfibers, designed for exacting stripline and microstrip circuit applications. The randomly oriented microfibers result in exceptional dielectric constant uniformity.

The dielectric constant of RT/duroid 5880 laminates is uniform from panel to panel and is constant over a wide frequency range. Its low dissipation factor extends the usefulness of RT/duroid 5880 laminates to Ku-band and above.

RT/duroid 5880 laminates are easily cut, sheared and machined to shape. They are resistant to all solvents and reagents, hot or cold, normally used in etching printed circuits or in plating edges and holes.

2.Key Features

Ultra-Low Dielectric Constant: 2.2 ±0.02 at 10 GHz/23°C

Exceptional Low Loss: Dissipation factor of 0.0009 at 10GHz

Temperature Stability: Temperature coefficient of dielectric constant (TCDk) of -125 ppm/°C

Environmental Resistance: Low Moisture Absorption 0.02%

Thermal Performance: CTE X-axis 31 ppm/°C, Y-axis 48 ppm/°C, Z-axis 237 ppm/°C

High Temperature Capability: Td 500°C TGA

Safety Certified: UL 94-V0

Manufacturing: Lead free Process compatible

Material Consistency: Isotropic properties

3.Benefits

Frequency Stability: Uniform electrical properties over wide frequency range

Easy Fabrication: Easily cut, sheared and machined to shape

Chemical Resistance: Resistant to solvents and reagents used in etching or plating edges and holes

Environmental Durability: Ideal for high moisture environments

Proven Reliability: Well-established material with extensive application history

Optimal Performance: Lowest electrical loss for reinforced PTFE material

4.PCB Construction Details

| Parameter | Specification |

|---|---|

| Base Material | RT/duroid 5880 |

| Layer Count | 2 layers |

| Board Dimensions | 90mm × 90mm = 1PC, ±0.15mm |

| Minimum Trace/Space | 5/5 mils |

| Minimum Hole Size | 0.3mm |

| Blind Vias | No |

| Finished Board Thickness | 1.6mm |

| Finished Cu Weight | 1oz (1.4 mils) |

| Via Plating Thickness | 20 μm |

| Surface Finish | Immersion Gold |

| Top Silkscreen | No |

| Bottom Silkscreen | No |

| Top Solder Mask | No |

| Bottom Solder Mask | No |

| Electrical Test | 100% tested prior to shipment |

5.PCB Stackup (12-Layer Rigid Structure)

Copper Layer 1 - 35 μm

RT/duroid 5880 - 5.575 mm (62mil)

Copper Layer 2 - 35 μm

6.PCB Statistics:

Components: 16

Total Pads: 53

Thru Hole Pads: 37

Top SMT Pads: 16

Bottom SMT Pads: 0

Vias: 49

Nets: 2

7.Typical Applications

Commercial Airline Broadband Antennas

Microstrip and Stripline Circuits

Millimeter Wave Applications

Radar Systems

Guidance Systems

Point to Point Digital Radio Antennas

8.Quality Assurance

Artwork Format: Gerber RS-274-X

Quality Standard: IPC-Class-2

Availability: Worldwide